Light Gauge Steel Frame (LGSF) is a cold rolled load bearing steel framed wall system with an established history as an innovative and reliable construction material in World. The inherent strength and design flexibility of LGSF construction enables increased spans, custom openings, curved walls and a variety of external architectural façade treatments; making it a versatile choice of construction material.

Our design philosophy is focused on rationalising the structural elements within the building to provide a more efficient construction programme and cost effective build methodology.

We provide a whole structure solution for your construction project.

From custom design solutions, modelling and methodology, to manufacture and installation.

Champion Prefabs provides a whole structure solution, from design to installation. We can help your design team adapt an existing building design into LGSF, or support your architect to design a bespoke LGSF building. Alternatively, you can engage our design team to work on a custom LGSF solution for your project.

Our team takes a collaborative approach to onsite construction. Working with the builder to develop a realistic and achievable construction programme that fully utilises the benefits of the LGSF structural solution. We offer a full structural methodology, including concrete supple and place, reinforcement steel, structural steel, LGSF load bearing wall system and roof framing.

Champion Prefabs team specialises in the manufacture and installation of LGSF systems for residential and commercial projects. During installation, our team employs a dry construction methodology with minimal wastage. Our ‘just in time’ delivery model means less manual handling and requires less onsite materials storage and set down area.

a. Wall Solution

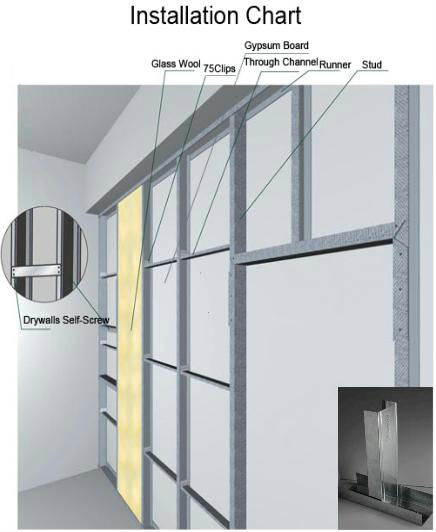

RF Wall is a high performance lightweight interior wall system consisting of a GI steel frame, encased in gypsum plasterboards on either side attached with self-drilling RF Walls screws.

HOW TO BUILD A WALL

Step 1: Framing using high performance LGSA Premium Steel™ studs and channels

Step 2: Management of services and provisioning for planned loading

Step 3: Install insulation in the cavity to enhance performance

Step 4: Install gypsum plasterboards on both sides

Step 5: Do jointing and finishing on the joints

Step 6: Finished wall

B. Structural Wall System

C. Partition wall system

Cold-formed sheet steel is an easy to handle, economical, non-combustible, high quality alternate to more traditional framing materials. Steel framing offers a strong, accurate, dimensionally stable and durable framing system.

A. Roof system

B. Structural Floor Systems

C. Wall, Floor and Truss Kits Material List

D. Joist Kits

c. Sheathing and Insulation products

Champion Prefabs unites a global network of inventive and highly skilled building engineers and design specialists.

Our Engineering team has engineers from african, gulf and asian countries who have worked with a range of clients to deliver innovative solutions to world-leading infrastructure design projects across the globe.

The Champion Prefabs Green Building Products divisional operations are one-stop shops for all light-steel engineering needs.

1. Architecture Engineering Services

2. Steel Detailing

3. Foundation Designing

4. CNC Drawing ( Framecad , Howick , Scottsdale )

5. MEP Drawing and Shop drawing

6. Millwork drawing services

7. Fabrication drawings

8. Manufacturing Drawings

9. Connection design / Steel detailing

Our operation is divided in three aspects

1. Framing design

10. Structure engineering services

11. On site inspection.

Our team of professionals can handle mechanical drawing or engineering drawing tasks that you present to us at a price that’s more than worth it.

| The Impact of Good Insulation on Energy Saving in Airconditioners | ||||||

| Delta Temperature | Energy Savings | Units Saved/day | Unit Cost (INR/Unit) | Amt Saved/day (INR) | Amt Saved/Month (INR) | Amt Saved/Year (INR) |

| 2 Degree Temp reduction | 17% | 7.65 | 10.00 | 76.50 | 2,295.00 | 27,922.50 |

| 3 Degree Temp reduction | 23% | 10.35 | 10.00 | 103.50 | 3,105.00 | 37,777.50 |

| 5 Degree Temp reduction | 33% | 14.85 | 10.00 | 148.50 | 4,455.00 | 54,202.50 |

| 10 Degree Temp reduction | 50% | 22.50 | 10.00 | 225.00 | 6,750.00 | 82,125.00 |

| Considering outdoor temperature of 35 degrees for a typical 2BHK house with 3 Airconditioners with total 4.5 Ton Capacity | ||||||

| Comparison of Weight for a 4 Storied Building designed with LGS and RCC | |||

| Weight Comparison of RCC Vs LGS | RCC | LGS | % Saving |

| Concrete Weight in Foundation (Tons) | 420 | 296 | 29% |

| Building Weight of Structural Materials (Kg/Sq.m) | 960 | 435 | 55% |

| Floor Slab weight (Tons) | 425 | 232 | 45% |

Project Name : LGS/CFS duplex house

Carpet Area : 2000 SqFT

Technology : LGS steel structure with Light foam insulation walls

Duration : 60 days

Location : Visit Now

CHAMPIONS GREEN COUNTY

Yeluvalli, Nandi Hobli, NH 7

Chikkaballapur Taluka

Chikkaballapur Dist

Karnataka – India

© 2025 Champion Prefabs. All Rights Reserved.